Introduction to Stainless Steel Fiber Optic Test Cables

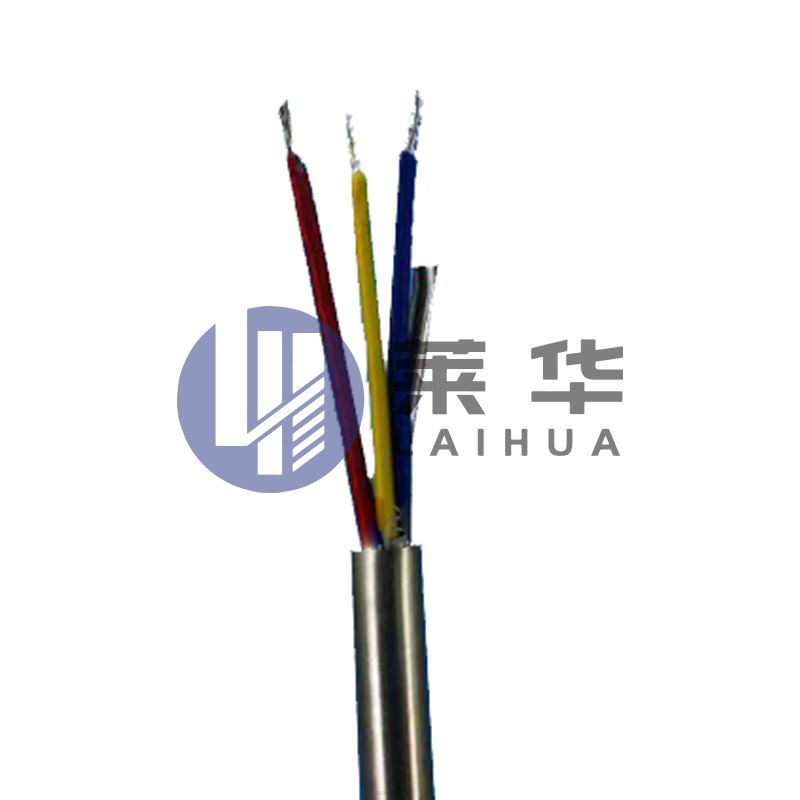

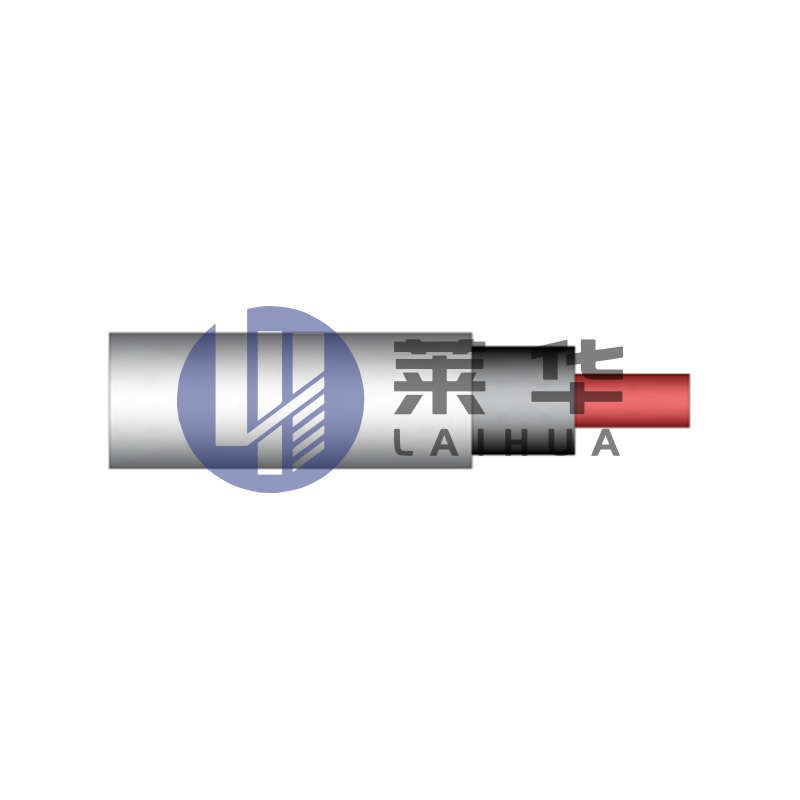

In the world of fiber optic network testing and maintenance, having reliable equipment is crucial. Stainless steel fiber optic testing cables have emerged as the preferred choice for professionals who demand durability and precision in their optical measurements. Unlike standard fiber optic patch cords, these ruggedized test cables feature stainless steel connectors that withstand repeated mating cycles, harsh environments, and provide consistent performance for accurate loss measurements.

When searching for durable fiber test leads or industrial-grade optical test cables, stainless steel variants consistently rank as top performers. Their robust construction makes them ideal for field technicians, data center engineers, and telecom professionals who need equipment that won't fail during critical testing procedures.

Key Benefits of Stainless Steel Fiber Test Cables

Understanding why stainless steel fiber optic test cables outperform their plastic counterparts helps professionals make informed purchasing decisions. Here are the primary advantages:

Superior Durability

The stainless steel connector ferrules and housings resist wear from repeated insertions, making these cables perfect for high-cycle testing applications. While plastic connectors might degrade after hundreds of matings, stainless steel versions can withstand thousands of insertions without performance degradation.

Enhanced Measurement Accuracy

Stainless steel provides better alignment of fiber cores during testing, reducing insertion loss variability. This results in more consistent and reliable measurements when performing optical loss testing or OTDR trace analysis.

Environmental Resistance

These cables perform reliably in extreme temperatures, high humidity, and dirty environments where plastic connectors might warp or collect contaminants. The stainless steel construction resists corrosion from salt spray, chemicals, and other harsh substances encountered in industrial fiber optic testing scenarios.

Long-Term Cost Savings

While the initial investment is higher than plastic test cables, stainless steel versions offer better total cost of ownership due to their extended service life and reduced replacement frequency.

Applications of Stainless Steel Fiber Test Cables

These specialized cables find use in numerous professional scenarios where reliable fiber optic testing is critical:

- Telecom network installation and maintenance - For precise loss measurements during turn-up and troubleshooting

- Data center certification - Ensuring fiber channel performance meets TIA/EIA standards

- Military and aerospace applications - Where ruggedized fiber test equipment is mandatory

- Industrial automation systems - Testing fiber networks in manufacturing environments

- Oil and gas installations - For fiber monitoring systems in harsh offshore conditions

- Long-haul network testing - Providing stable reference cables for OTDR testing

Professionals searching for extreme environment fiber test cables or military-grade optical test leads will find stainless steel versions meet their stringent requirements.

Choosing the Right Stainless Steel Test Cable

Not all stainless steel fiber test cables are created equal. Consider these factors when selecting your test cable:

| Feature | Consideration | Recommendation |

| Connector Type | Must match equipment interfaces | LC for high-density, SC for general use, MTP/MPO for multi-fiber |

| Ferrule Material | Affects durability and performance | Stainless steel with zirconia sleeve for best results |

| Cable Length | Impacts convenience and loss | 1-2m for general use, longer for specific applications |

| Fiber Type | Must match network fiber | SM (9/125) for single-mode, MM (50/125 or 62.5/125) for multi-mode |

| Polish Type | Affects connector performance | UPC for most applications, APC for CATV/PON networks |

| Jacket Material | Determines cable flexibility and protection | OFNR-rated for general use, armored for harsh environments |

When searching for precision fiber test leads or low-loss reference cables, pay special attention to the connector polish and ferrule quality, as these directly impact measurement accuracy.

Maintenance Tips for Long-Lasting Performance

Proper care extends the service life of your stainless steel fiber optic test cables:

Regular Cleaning

Use appropriate fiber optic cleaning tools - lint-free wipes with isopropyl alcohol for connectors, and cassette cleaners for ferrules. Avoid using regular compressed air which can introduce contaminants.

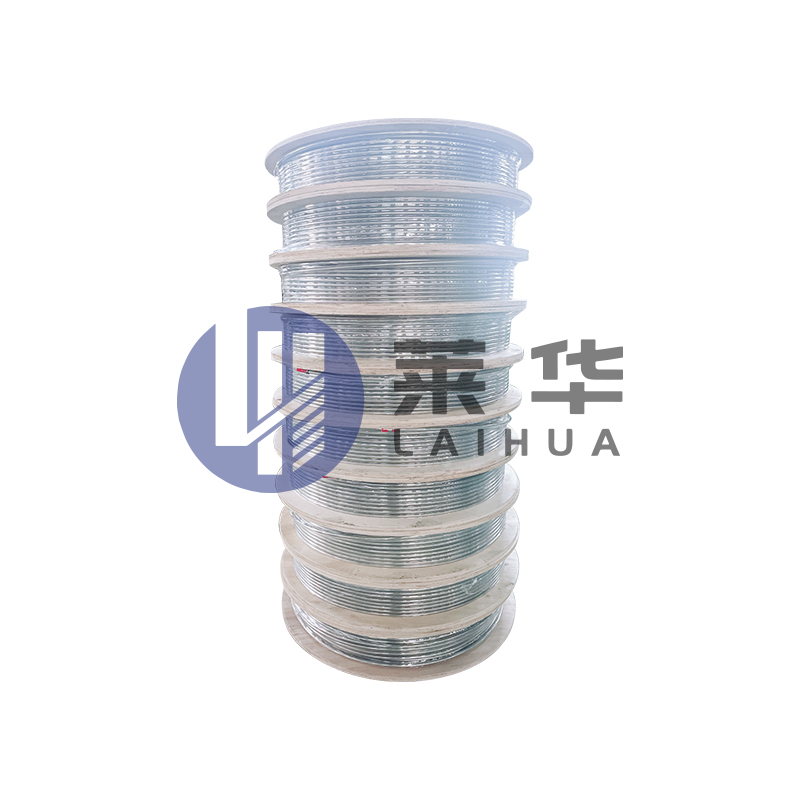

Proper Storage

Store cables in protective cases when not in use. Avoid bending beyond the minimum bend radius (typically 20x cable diameter). Use fiber optic cable organizers to prevent kinks and stress.

Connection Handling

Always use the strain relief boot when connecting/disconnecting. Never pull directly on the cable. For high-precision fiber testing, consider using torque wrenches for consistent connection tightness.

Periodic Inspection

Use a fiber inspection microscope (at least 200x magnification) to check for scratches, pits, or contamination on ferrule end faces. Even stainless steel connectors can develop issues over time.

Common Mistakes to Avoid with Test Cables

Even experienced technicians sometimes make these errors with their fiber test cables:

- Mixing cable types during testing - Always use the same fiber type (SM/MM) and core size as the network being tested

- Neglecting connector inspection - Dirty or damaged connectors account for most measurement errors

- Over-tightening connections - This can distort ferrules and affect alignment

- Using damaged cables as reference - Compromised test cables invalidate all subsequent measurements

- Ignoring temperature effects - Allow cables to acclimate when moving between extreme environments

Searching for fiber optic testing best practices or how to maintain test cables can yield additional tips for maximizing your equipment's lifespan.

Industry Standards and Certifications

Quality stainless steel fiber test cables should comply with relevant industry standards:

- TIA/EIA-568 - Covers general requirements for fiber optic components

- IEC 61300-3-35 - Addresses connector durability testing

- GR-326-CORE - Telcordia requirements for single-mode connectors

- MIL-STD-1678 - Military standard for fiber optic test equipment

- ISO 9001 - Quality management system certification for manufacturers

When evaluating certified fiber test equipment or standards-compliant test cables, verify these certifications with the manufacturer.

Future Trends in Fiber Optic Test Cables

The fiber optic testing industry continues to evolve, with several developments affecting test cable technology:

Higher Density Interfaces

As networks adopt more compact connectors like CS and SN, test cables must follow suit. Look for high-density fiber test solutions that maintain durability in smaller form factors.

Smart Test Cables

Emerging technologies embed microchips in connectors to track mating cycles, store calibration data, and even detect contamination. These intelligent fiber test cables could revolutionize maintenance procedures.

Advanced Materials

New stainless steel alloys and ceramic composites promise even greater durability and temperature stability for next-gen fiber test equipment.

Automated Testing Integration

Test cables designed specifically for use with robotic fiber handlers and automated test systems are gaining traction in high-volume production environments.

Conclusion

Stainless steel fiber optic testing cables represent a smart investment for any serious network professional. Their superior durability, measurement consistency, and environmental resistance make them ideal for demanding testing applications across telecom, data center, industrial, and military sectors. By selecting the right cable for your specific needs, maintaining it properly, and following industry best practices, you'll ensure accurate test results and reliable network performance for years to come.

Whether you're searching for ruggedized fiber test leads, precision reference cables, or industrial optical test solutions, stainless steel variants offer the performance and longevity that professionals require. As fiber networks continue to expand into more challenging environments, these robust test cables will remain an essential tool for maintaining optimal network performance.

英语

英语 西班牙语

西班牙语 阿拉伯语

阿拉伯语

Contact Us