Cat:Products

Continuous tubing, also known as flexible tubing or flexible tubing, is widely used in the fields of well workover, logging and drilling, etc. Its pro...

See Details

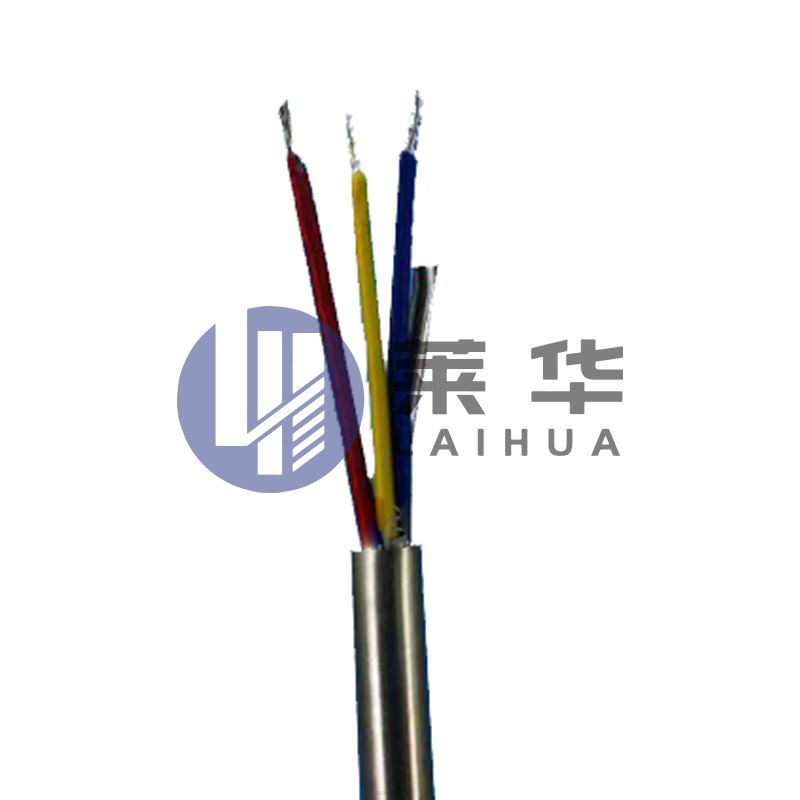

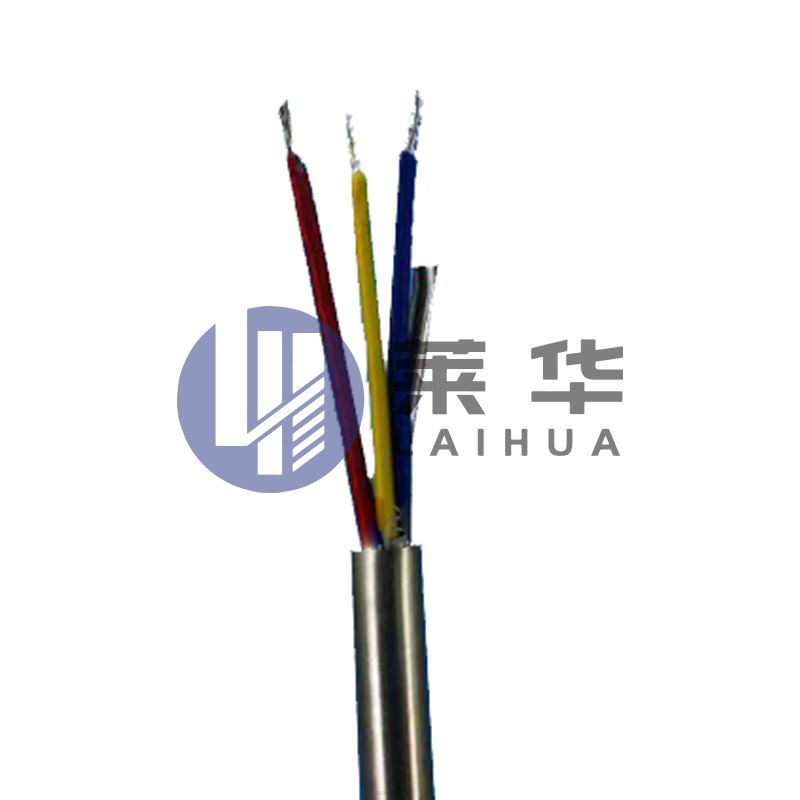

In the realm of fiber optic technology, testing cables serve as the crucial link between innovation and flawless performance. Among the myriad options available, stainless steel fiber optic testing cables have emerged as the quintessential choice for professionals demanding unparalleled resilience and accuracy. This article delves into the unique attributes, applications, and advantages of stainless steel fiber optic testing cables, underscoring why they stand supreme in rigorous testing environments.

Unyielding Strength Coupled with Precision

At the heart of the stainless steel fiber optic testing cable lies a fusion of robust engineering and optical finesse. Stainless steel, renowned for its exceptional tensile strength and corrosion resistance, forms the backbone of the cable’s protective sheath. This metallic armor shields the delicate fiber core from mechanical stresses, abrasions, and environmental aggressors that typically compromise conventional polymer-jacketed cables.

The intrinsic toughness of stainless steel ensures longevity even under relentless operational demands—be it frequent bending, twisting, or exposure to harsh chemicals. Unlike standard testing cables susceptible to micro-bends and signal attenuation, stainless steel variants maintain consistent optical performance. This steadfastness guarantees the integrity of test measurements, enabling engineers to pinpoint network faults with extraordinary precision.

Tailored for High-Stakes Environments

Fiber optic testing often unfolds in environments where reliability is non-negotiable. Industrial plants, military installations, and large-scale telecommunication projects necessitate testing equipment that withstands extremes. Stainless steel fiber optic testing cables rise to this challenge, delivering impeccable performance amidst temperature fluctuations, moisture, and physical impact.

The cable’s corrosion-resistant properties make it particularly invaluable in marine or chemical processing contexts, where exposure to corrosive agents is routine. Its impervious nature curtails the risk of cable degradation, thereby diminishing downtime and maintenance costs. For engineers and technicians, this translates to uninterrupted workflows and superior project outcomes.

Enhanced Flexibility Without Compromise

While stainless steel conjures images of rigidity, the engineering behind fiber optic testing cables ensures remarkable flexibility. The design incorporates finely woven stainless steel strands that confer tensile strength without sacrificing maneuverability. This ingenious construction allows testers to navigate confined spaces, conduit pathways, and intricate network layouts with ease.

Moreover, the stainless steel sheath effectively prevents kinking and crushing—common culprits behind fiber breakage. Such protection is crucial during the repetitive insertions and removals typical of testing cycles. The result is a cable that not only withstands physical demands but also preserves the fidelity of optical signals, elevating the accuracy of diagnostic procedures.

Superior Signal Integrity and Testing Accuracy

Stainless steel fiber optic testing cables are engineered to minimize signal loss, a paramount factor in the realm of optical testing. The internal fiber core benefits from a meticulously controlled environment, shielded by the stainless steel sheath from micro-bends and environmental interferences that cause attenuation.

In practice, this means clearer signal transmission and more reliable test results. Network engineers can detect even minute discrepancies in fiber integrity, splice quality, and connector performance. The heightened sensitivity afforded by stainless steel cables accelerates troubleshooting and enhances preventive maintenance protocols, ultimately bolstering network uptime and service quality.

Versatility Across Diverse Fiber Optic Applications

From single-mode to multimode fibers, stainless steel testing cables cater to a broad spectrum of fiber optic systems. Their adaptability makes them indispensable tools for certifying network installations, commissioning new infrastructures, and conducting routine maintenance.

Additionally, these cables accommodate various connector types, including SC, LC, ST, and MPO, offering seamless compatibility across equipment platforms. The convergence of ruggedness, flexibility, and optical excellence renders stainless steel fiber optic testing cables a universal asset in the fiber optic domain.

Economic and Operational Benefits

Though stainless steel fiber optic testing cables may command a premium upfront, their total cost of ownership reveals compelling value. Their durability curtails frequent replacements, reducing procurement cycles and inventory expenses. Simultaneously, enhanced test accuracy minimizes troubleshooting time and mitigates costly network outages.

By investing in stainless steel fiber optic testing cables, organizations safeguard their fiber optic assets with a robust, high-performance instrument. This strategic choice elevates operational efficiency, fortifies network reliability, and fosters confidence in critical communication infrastructures.

Stainless steel fiber optic testing cables epitomize the convergence of durability, precision, and adaptability. They transcend the limitations of conventional testing cables, providing an indispensable edge for professionals operating in demanding environments. For those seeking to elevate fiber optic testing to a realm of uncompromised quality, stainless steel cables present an unequivocal solution—engineered to endure, designed to perform.

Contact Us