Cat:Products

Continuous tubing, also known as flexible tubing or flexible tubing, is widely used in the fields of well workover, logging and drilling, etc. Its pro...

See Details

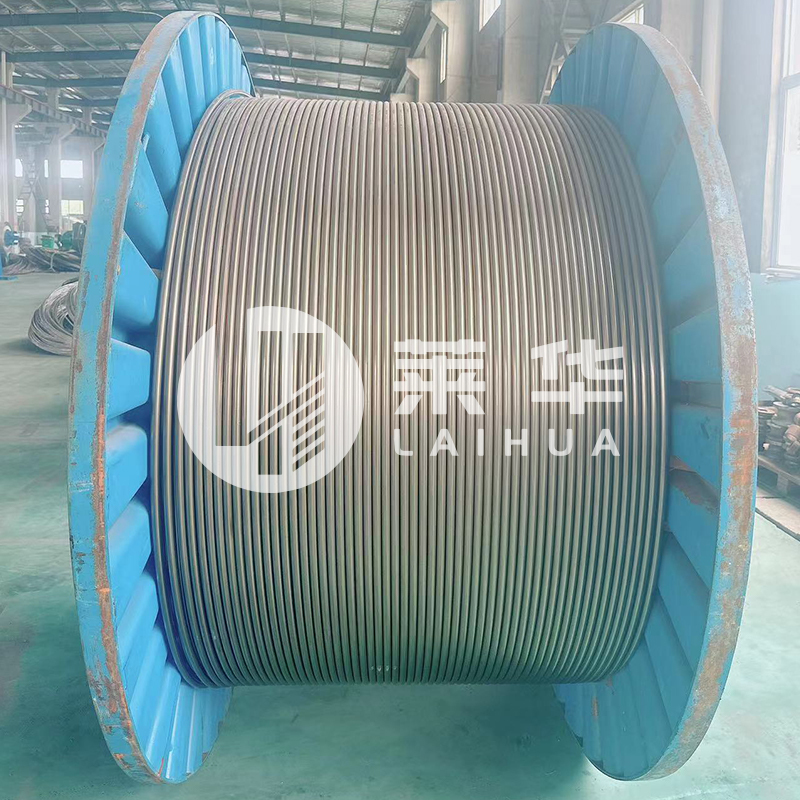

Stainless steel coil is widely used in industries ranging from construction to automotive manufacturing due to their durability, corrosion resistance, and versatility. If you're looking to understand stainless steel coils in detail, this guide covers everything from types and grades to applications and purchasing tips.

A stainless steel coil is a long, thin strip of stainless steel wound into a roll. These coils come in various widths, thicknesses, and finishes, making them suitable for different industrial and commercial applications. They are made from an alloy of iron, chromium, and other elements like nickel and molybdenum to enhance strength and corrosion resistance.

Stainless steel coils are categorized based on their microstructure and composition. The most common types include:

| Type | Key Properties | Common Uses |

| Austenitic Stainless Steel Coil | High corrosion resistance, non-magnetic, excellent formability | Kitchen equipment, chemical tanks, medical devices |

| Ferritic Stainless Steel Coil | Magnetic, moderate corrosion resistance, good strength | Automotive exhaust systems, industrial machinery |

| Martensitic Stainless Steel Coil | High strength, moderate corrosion resistance, heat-treatable | Cutlery, turbine blades, surgical instruments |

| Duplex Stainless Steel Coil | Combines austenitic and ferritic properties, high strength | Oil and gas pipelines, desalination plants |

Different grades of stainless steel coils offer varying levels of corrosion resistance, strength, and weldability. Below are some widely used grades:

| Grade | Type | Key Features |

| 304 Stainless Steel Coil | Austenitic | Excellent corrosion resistance, versatile, food-grade |

| 316 Stainless Steel Coil | Austenitic | Superior corrosion resistance (marine environments), contains molybdenum |

| 430 Stainless Steel Coil | Ferritic | Cost-effective, good formability, magnetic |

| 410 Stainless Steel Coil | Martensitic | High strength, heat-treatable, moderate corrosion resistance |

Stainless steel coils are used in numerous industries due to their adaptability and durability. Some key applications include:

Selecting the right stainless steel coil depends on several factors:

The surface finish of a stainless steel coil affects its appearance and performance. Common finishes include:

| Finish | Description | Best For |

| No. 1 (Hot Rolled Annealed) | Rough, dull surface | Industrial applications where appearance isn't critical |

| No. 2B (Cold Rolled, Bright Annealed) | Smooth, reflective surface | Appliances, kitchen equipment, medical devices |

| No. 4 (Brushed Finish) | Fine parallel polishing lines | Architectural panels, elevators, decorative trims |

| BA (Bright Annealed) | Mirror-like, highly reflective | Luxury appliances, automotive trim |

Stainless steel coils come in various thicknesses and widths to suit different needs. Below are common dimensions:

| Thickness (mm) | Common Width (mm) | Typical Applications |

| 0.3 – 0.8 | 600 – 1,250 | Household appliances, automotive trim |

| 1.0 – 3.0 | 1,000 – 1,500 | Construction panels, industrial machinery |

| 3.0 – 6.0 | 1,500 – 2,000 | Heavy-duty industrial use, shipbuilding |

To ensure longevity, stainless steel coils require proper maintenance:

When purchasing stainless steel coils, consider the following:

Stainless steel coils are essential in modern manufacturing and construction due to their durability, corrosion resistance, and versatility. By understanding the different types, grades, finishes, and applications, you can make an informed decision when purchasing stainless steel coils for your project.

Contact Us