Cat:Products

Continuous tubing, also known as flexible tubing or flexible tubing, is widely used in the fields of well workover, logging and drilling, etc. Its pro...

See Details

In modern construction, plumbing, and industrial applications, the choice of piping material significantly impacts efficiency, durability, and cost. Among emerging solutions, stainless steel wrapped plastic pipe has gained attention as an innovative alternative to traditional piping materials such as plain steel, copper, or unreinforced plastic.

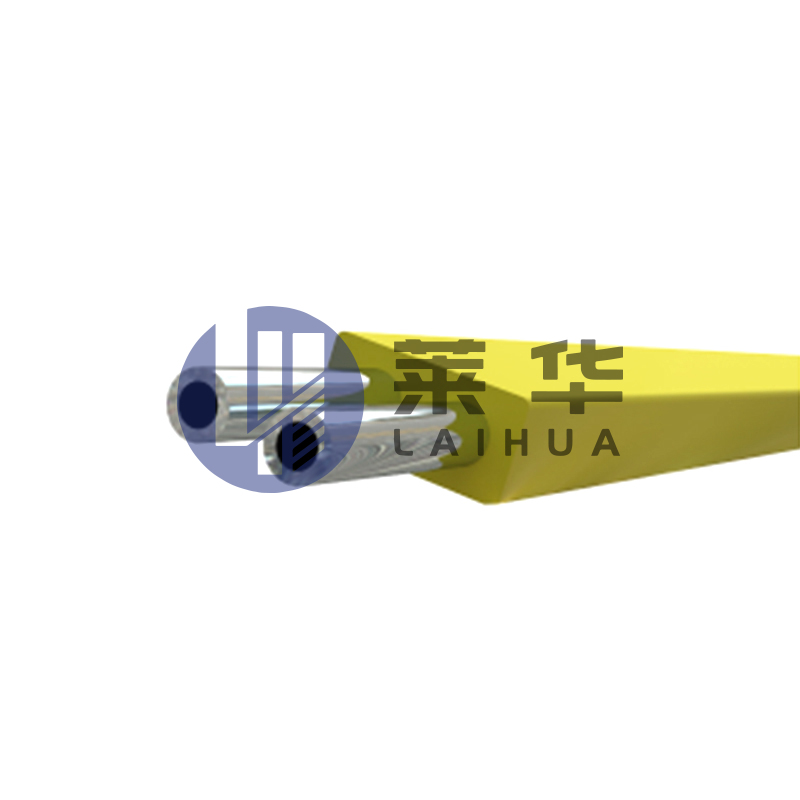

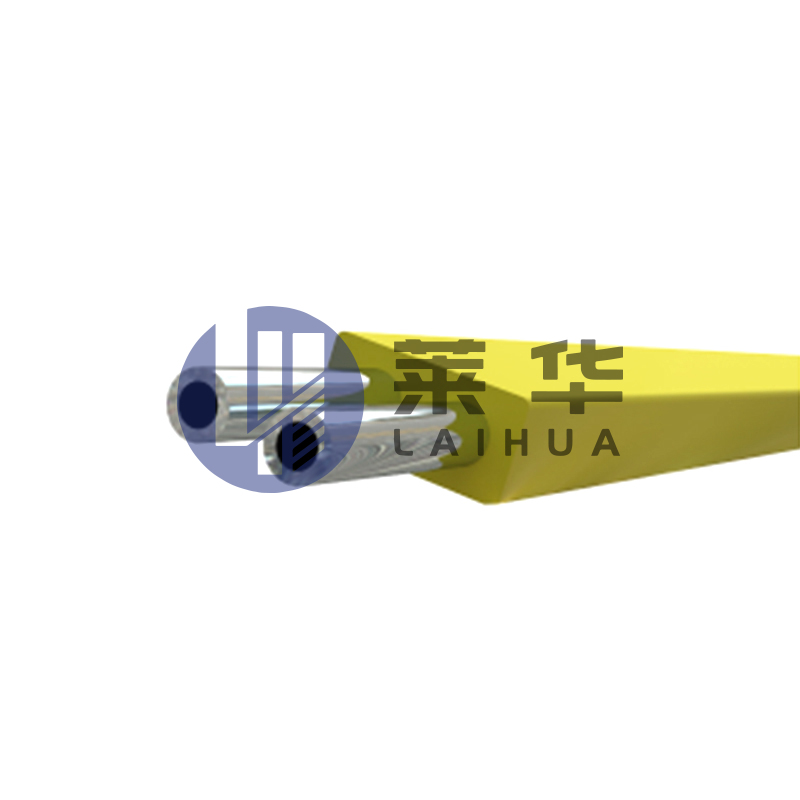

Stainless steel wrapped plastic pipes combine a plastic core—typically polyethylene (PE) or polypropylene (PP)—with a thin layer of stainless steel wrapped around the outside. This hybrid design leverages the advantages of both materials: the flexibility and corrosion resistance of plastic and the strength, rigidity, and protective properties of stainless steel.

The stainless steel layer can be applied in different ways, such as helically wound strips or continuous seamless wrapping. The adhesion between the metal and plastic ensures structural integrity, reducing deformation under pressure while maintaining corrosion resistance.

Traditional pipes such as steel or copper are known for their high mechanical strength, making them suitable for high-pressure applications. However, they are prone to corrosion over time, particularly in environments with moisture or chemicals.

Stainless steel wrapped plastic pipes, on the other hand, combine the tensile strength of stainless steel with the inherent chemical resistance of plastic. This hybrid construction offers comparable pressure resistance to steel pipes while maintaining long-term durability in corrosive environments.

Corrosion is a critical factor in pipe longevity. Steel pipes, especially carbon steel, require protective coatings or cathodic protection to resist corrosion. Copper pipes naturally resist corrosion but can be affected by acidic water or certain soil conditions.

In contrast, the plastic core of stainless steel wrapped pipes is inherently corrosion-resistant, while the stainless steel outer layer protects against physical damage and additional corrosion. This makes them highly suitable for environments with high humidity, salt exposure, or chemical contamination.

Plastic pipes generally have lower thermal resistance and can deform under high temperatures, limiting their use in certain industrial applications. Stainless steel wrapped plastic pipes improve thermal tolerance, enabling operation under higher temperature ranges without significant deformation.

Chemically, the plastic core provides resistance to a wide variety of substances, from water to industrial chemicals, reducing the risk of reactions that could compromise structural integrity. Traditional pipes may require additional linings or treatments to achieve similar chemical resistance.

Installation methods vary between pipe types and can influence labor cost, time, and reliability.

Steel and copper pipes require welding, soldering, or threading during installation. These processes demand skilled labor and may involve safety risks. Misalignment or poor joints can also lead to leaks or failures over time.

Stainless steel wrapped plastic pipes are typically lighter than traditional metal pipes, reducing handling difficulty and installation time. They can often be joined using mechanical fittings, compression joints, or adhesive bonding, depending on the design. This reduces the need for welding or soldering while maintaining reliable seals. Their flexibility also allows for easier navigation around obstacles, minimizing the number of joints required.

Maintenance requirements significantly impact long-term operational costs.

Steel pipes often require regular inspection and anti-corrosion treatment. Copper pipes, while more resistant, may require monitoring in acidic water systems to prevent pitting or pinhole leaks. Both types may eventually suffer from scaling, rust, or mechanical damage that necessitates repair or replacement.

The hybrid design of stainless steel wrapped plastic pipes reduces maintenance needs. The plastic core resists corrosion and scaling, while the stainless steel outer layer protects against scratches, punctures, and UV degradation. As a result, these pipes often have a longer service life with minimal inspection or treatment, especially in corrosive or industrial environments.

Initial material cost is one factor, but total cost of ownership should consider installation, maintenance, and replacement.

Environmental considerations are increasingly important in construction and industry. Stainless steel wrapped plastic pipes are lightweight, reducing transportation energy. Their corrosion resistance prevents leaks that could cause environmental contamination. Unlike copper, they do not leach metals into water systems.

Traditional pipes may require more frequent replacement and maintenance, which can increase material consumption and environmental impact.

Stainless steel wrapped plastic pipes are particularly advantageous in applications that combine high pressure, corrosive substances, and temperature variation. Examples include:

Traditional pipes may suffice in less demanding environments, such as residential water supply or low-pressure industrial lines, but their long-term durability in harsh conditions is often lower.

While these hybrid pipes offer many benefits, they are not universally suitable. Limitations include:

Understanding the application requirements is essential for selecting the most appropriate piping material.

Stainless steel wrapped plastic pipes provide a balanced solution that combines strength, flexibility, corrosion resistance, and ease of installation. Compared with traditional pipes, they excel in harsh or corrosive environments, reduce maintenance requirements, and offer long-term cost-effectiveness. Traditional steel and copper pipes remain suitable for applications requiring extremely high pressure or temperatures, but the hybrid design of stainless steel wrapped plastic pipes makes them increasingly attractive for modern industrial, commercial, and residential applications.

By carefully considering the environment, operational conditions, and lifecycle costs, engineers, contractors, and facility managers can make informed decisions that maximize performance and longevity while minimizing maintenance and environmental impact.

Contact Us