Cat:Products

Continuous tubing, also known as flexible tubing or flexible tubing, is widely used in the fields of well workover, logging and drilling, etc. Its pro...

See Details

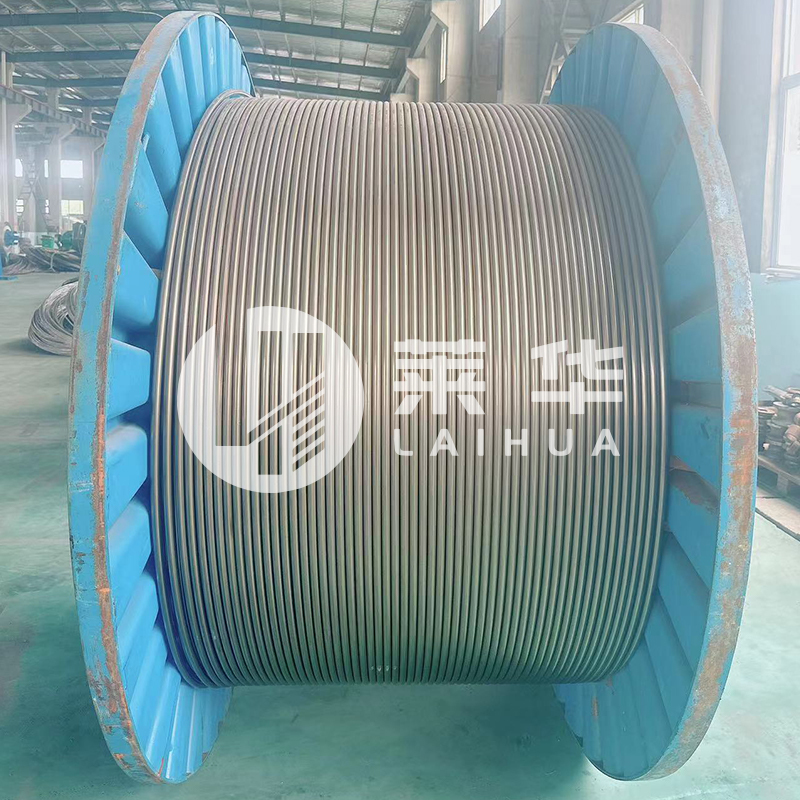

Stainless steel welded coils are continuous lengths of stainless steel that have been formed and welded to create a uniform product. These coils are widely used in various industries due to their durability, corrosion resistance, and versatility. Unlike seamless coils, welded coils are made by joining strips of stainless steel through welding processes.

Different grades of stainless steel are used in welded coils, each offering unique properties:

| Grade | Characteristics | Common Applications |

| 304 | Excellent corrosion resistance, good formability | Food processing, kitchen equipment |

| 316 | Higher corrosion resistance, especially against chlorides | Marine applications, chemical processing |

| 430 | Good corrosion resistance, magnetic properties | Automotive trim, appliances |

| 409 | Good heat resistance, lower cost | Automotive exhaust systems |

The production of stainless steel welded coils involves several key steps:

| Step | Description | Importance |

| 1. Material Preparation | Stainless steel strips are cleaned and prepared | Ensures proper welding and surface quality |

| 2. Forming | Strips are formed into cylindrical shapes | Creates the basic coil structure |

| 3. Welding | Edges are joined using specialized welding techniques | Determines the strength and integrity of the coil |

| 4. Heat Treatment | Coils undergo annealing to relieve stresses | Improves mechanical properties |

| 5. Finishing | Surface treatments are applied | Enhances appearance and corrosion resistance |

Welded coils offer several benefits over other forms of stainless steel products:

| Advantage | Description |

| Cost-Effective | Generally more affordable than seamless alternatives |

| Consistent Quality | Uniform thickness and properties throughout |

| Wide Size Range | Available in various widths and thicknesses |

| Efficient Production | Can be produced in continuous lengths |

| Good Weldability | Designed specifically for welded applications |

These versatile products find use in numerous industries:

| Industry | Application | Reason for Use |

| Construction | Architectural cladding, roofing | Durability, aesthetic appeal |

| Automotive | Exhaust systems, trim components | Heat and corrosion resistance |

| Food Processing | Processing equipment, storage tanks | Hygienic, easy to clean |

| Chemical | Piping, reaction vessels | Resistance to corrosive chemicals |

| Medical | Equipment housings, surgical tools | Sterilizable, non-reactive |

Consider these factors when selecting stainless steel welded coils:

| Factor | Considerations |

| Material Grade | Match to environmental conditions and application requirements |

| Thickness | Determine based on structural needs and forming requirements |

| Width | Choose to minimize waste and maximize efficiency |

| Surface Finish | Select based on aesthetic and functional needs |

| Certifications | Ensure compliance with industry standards |

Proper maintenance extends the life of stainless steel products:

| Maintenance Task | Frequency | Purpose |

| Regular Cleaning | As needed | Remove contaminants that could cause corrosion |

| Inspection | Annually | Identify potential issues early |

| Passivation | After fabrication | Restore protective oxide layer |

| Proper Storage | Always | Prevent damage and contamination |

Understanding potential issues helps in prevention and troubleshooting:

| Challenge | Causes | Solutions |

| Weld Defects | Improper welding parameters, contamination | Quality control, proper welding procedures |

| Corrosion | Exposure to harsh environments, improper grade selection | Material selection, protective coatings |

| Dimensional Issues | Improper forming, thermal distortion | Process control, proper tooling |

| Surface Imperfections | Handling damage, manufacturing defects | Careful handling, quality inspections |

The industry continues to evolve with new developments:

| Trend | Description | Potential Impact |

| Advanced Alloys | Development of higher performance stainless steels | Extended applications in extreme environments |

| Automated Production | Increased use of robotics and AI in manufacturing | Higher consistency, lower costs |

| Sustainable Practices | More recycling and energy-efficient production | Reduced environmental impact |

| Smart Manufacturing | Integration of IoT for quality monitoring | Improved traceability and quality control |

Stainless steel welded coils offer a versatile and cost-effective solution for numerous industrial applications. By understanding the different grades, manufacturing processes, and proper selection criteria, users can maximize the benefits of these products. Proper maintenance and awareness of potential challenges ensure long-lasting performance. As technology advances, we can expect even more innovative applications and improvements in stainless steel welded coil production.

Contact Us